The RGA is usually stored in the clean room on the lower

shelf with the T-piece and pin hole already attatched. The RS-232 and power

cables should also be still connect to the RGA. The NEC laptop can normally

be found on the floor of the service building staff office in its black

cloth bag.

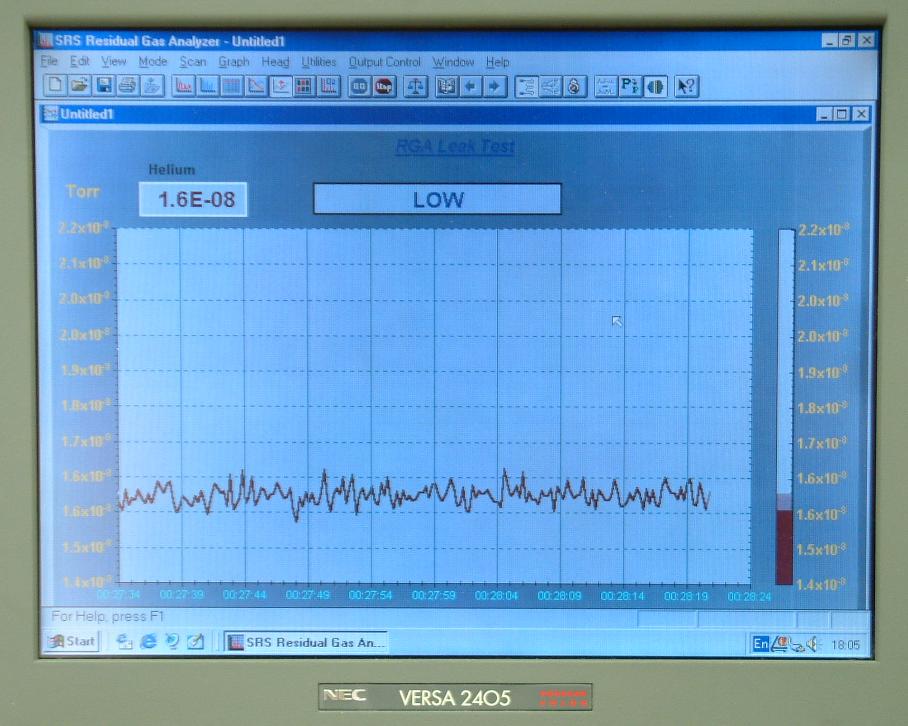

After closing NOTCam it is necessary to pump the instrument for a while.

A period of one hour should normally be sufficent, this will allow the pump

to reach its maximum normal operating speed of 75Krpm and a pressure in

the instrument of about 8x10-2 mbars. Once these conditions are

met you can proceed with the leak test.